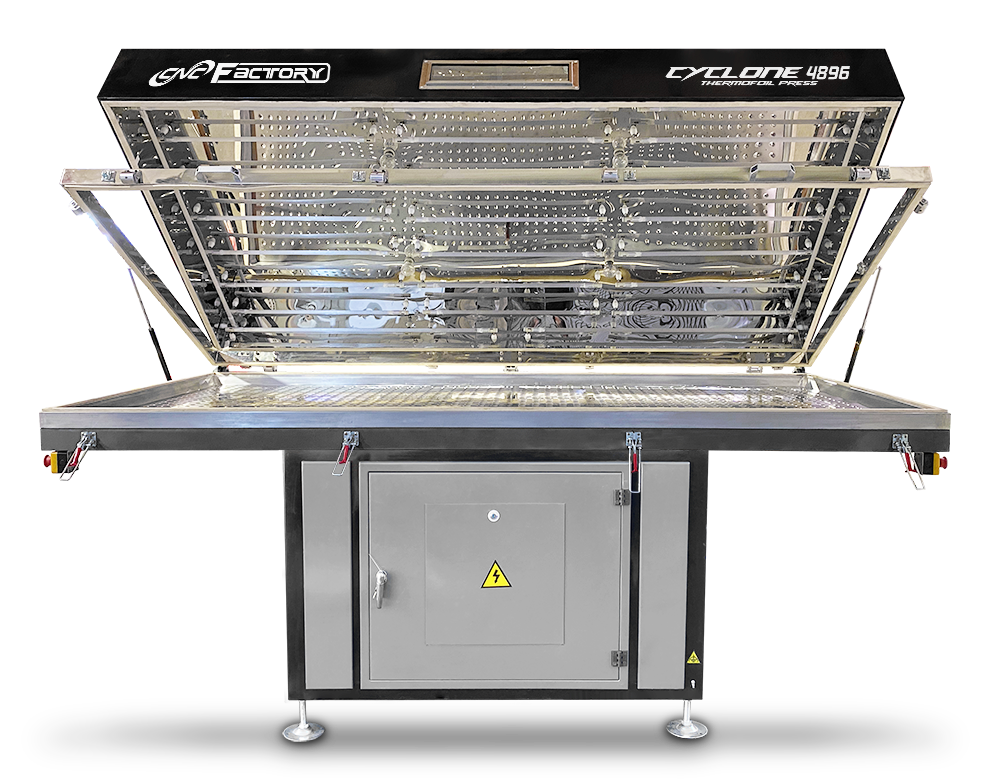

Thermofoil Press

Short-Cycle, High-Yield 3D Pressing. From kitchen cabinet doors, closet doors, store fixtures, and office furniture tops, the Cyclone can press virtually any 3D shape using PVC sheets, rigid sheets, PS sheets, acrylic, ABS and wood veneers. Easy to use, a single operator can produce over 300 pieces per 8 hour shift.

BUILD YOUR OWN CYCLONE 4896

Request a Consultation

Download Specs Sheet

Download Brochure

Watch the Video

Share this

Footprint |

|||

| Footprint | 2750mm L x 1600mm W x 1600mm H | ||

|---|---|---|---|

Specifications |

|||

| Process Area | 48” x 96”, customizable | Heating Lamps | 800W per lamp, total of 13.6W |

| Vacuum Pump | 2.2KW. Pressure of -0.08Mpa | ||

Mechanical/Electrical Requirements |

|||

| Power | 208-240 volts, 3-phase + common, 60amp | Air | 8 bar, 9cfm, 120 psi |

| Production Upgrades | Caster Wheels |

|---|---|

|

An optional upgrade to make the Cyclone mobile. However, this would increase the height of the machine. Make sure added mobility does not hamper your access to the work area. |

Support & Warranty |

|||

| Machine Warranty | 18 months | Support | 2-year machine support

Free CNC University training On-site support options available Online Knowledge Center access |

|---|---|---|---|

Not a lot. After your air and power are hooked up, you just need to conduct a few test runs to see what the ideal settings for your unique material and thermofoil are. Once these settings are determined, you can operate the machine like clockwork. Anyone can be trained to use the Cyclone in just a few hours.

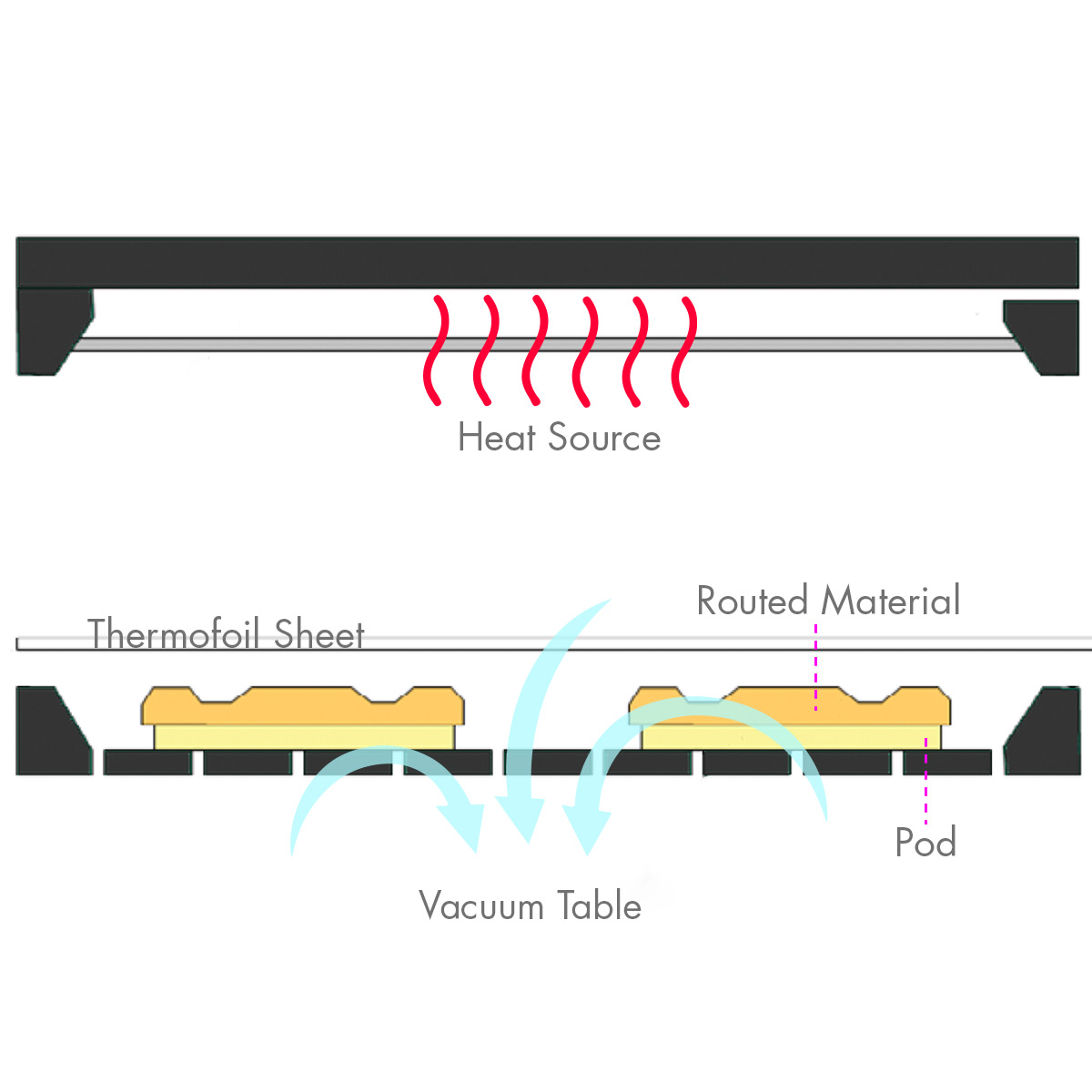

Thermofoil itself is a thin sheet of PVC (vinyl). Despite the name, it doesn’t contain metal. To make thermofoil products, a sheet of thermofoil is applied to a substrate, typically medium-density fiberboard (MDF). The covered substrate is placed in a heated vacuum chamber that causes the thermofoil to fuse to the substrate. The heat on top softens the sheet and makes it more pliable. The infrared quartz heating elements are also arranged to avoid cool spots that are common in lesser-engineered presses.

This repeated cycle of heating and vacuum allows the sheet to soften and take the form of the substrate. It’s a calculated dance— making the thermofoil too soft too fast can create a tear due to the strong vacuum pull. On the contrary, if the thermofoil is not pliant enough or if there is no sufficient vacuum where you need it, it will fail to take the exact shape of the substrate material.

We recommend just checking your oil and air filters at least once a month. Our CSA-certified reinforced filament incandescent bulbs need replacement after 3,000 hours of use. All these consumables should always be on stock at CNC Factory.

We are happy to answer any questions you may have.

714-581-5999

4021 West Chandler Ave, Santa Ana, CA 92704

sales@cncfactory.com

We also offer in-house and 3rd party financing to cover 50-100% of your purchases.

See Financing Options