CNC Routers

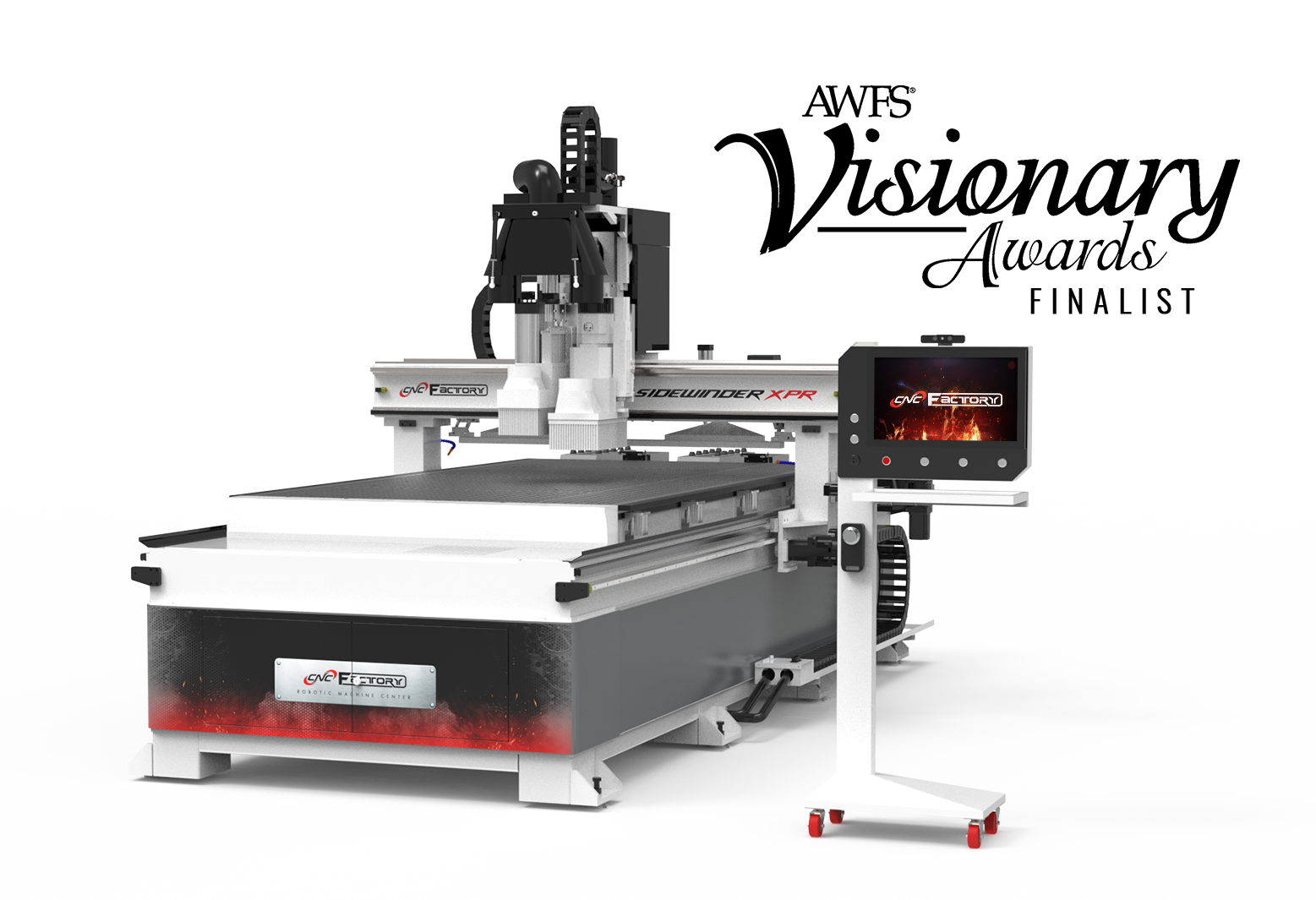

Precise. Driverless. Expandable. Designed for factory profitability, speed, and ease of use for the woodworker, it grows as you grow with its arsenal of ‘anytime upgrades’ which you can plug & play when needed. When fully upgraded, the Sidewinder eliminates all the heavy lifting and critical thinking required of a skilled operator.

BUILD YOUR OWN SIDEWINDER

Request a Consultation

Download Specs Sheet

Download Brochure

Watch the Video

Share this

Footprint & Weights |

|||

| 4’x8’ Table | 99.5” x 152” x 101”H (7200lbs) | 4’x10’ Table | 99.5” x 176” x 101”H (7600lbs) |

|---|---|---|---|

| 5’x10’ Table | 111.5” x 176” x 101”H (7800lbs) | 5’x12’ Table | 111.5” x 199” x 101”H (8500lbs) |

Specifications |

|||

| Number of axes | 3 | Table sizes | 4’ x 8’ ft

4’ x 10’ ft 5’ x 10’ ft 5’ x 12’ ft Custom |

| Spindle | 12HP ATC air-cooled spindle | Speed | 1200 IPM cutting & 2200 IPM rapid movement |

| Drive motor | Yaskawa Sigma 7 series w/ absolute encoder | Lubrication | Pressurized, automatic control |

| ATC tool changer | 8 Position Auto Rack Tool Changer with 8-second tool changes

8 ISO ER-30 tool holders, ER wrench included Auto tool length measurement sensor included |

Controller | Mobile controller with safety lights & wireless MPG remote

PC/Windows front end 21” touchscreen HD digital camera for remote access Ethernet, WiFi, USB connectivity |

| Vacuum System | Intelligent zoned, high-flow vacuum system (with touch screen valve controls) | Rail System | 5G helical rack and pinion (X & Y axes) |

| Other inclusions | Additional vacuum port

Onboard A/C Pop-up positioning pins Roller wheels for loading |

Software | Built-in KCD software option

Compatible with virtually all CAD softwares |

Mechanical/Electrical Requirements |

|||

| Power | 208-240 volts, 3 phase. 30amps.

Single phase option available for additional charge. |

Air | 8 bar, 9cfm, 120 psi |

| Dust Collection | 2500 cfm for main 6” port

Gravity for the secondary 4” port Gravity for the (optional) unloading table 4” port |

||

| Production Upgrades | Custom table size

Custom gantry height Single-phase power conversion Horizontal side spindle 4th axis on spindle Aggregate head rotary on spindle |

Plug & Play Upgrades | 9-Position drill block

12-tool ATC 4-Port marking block V300 Vacuum pump Mister kit Laser module Robotic material alignment Robotic loading arm Robotic material sensing dust hood Hydraulic automated loading table Unloading conveyor with material sensing |

|---|---|---|---|

| Tooling | Deluche Vision Marking Tool

Cabinet Startup tooling kit Cabinet & Drill block tooling kit |

||

Support & Warranty |

|||

| Machine Warranty | 18 months | Support | Free lifetime technical support (phone & email)

Free CNC University training 5-year Advanced Exchange Program for parts & tooling On-site support options available Online Knowledge Center access |

|---|---|---|---|

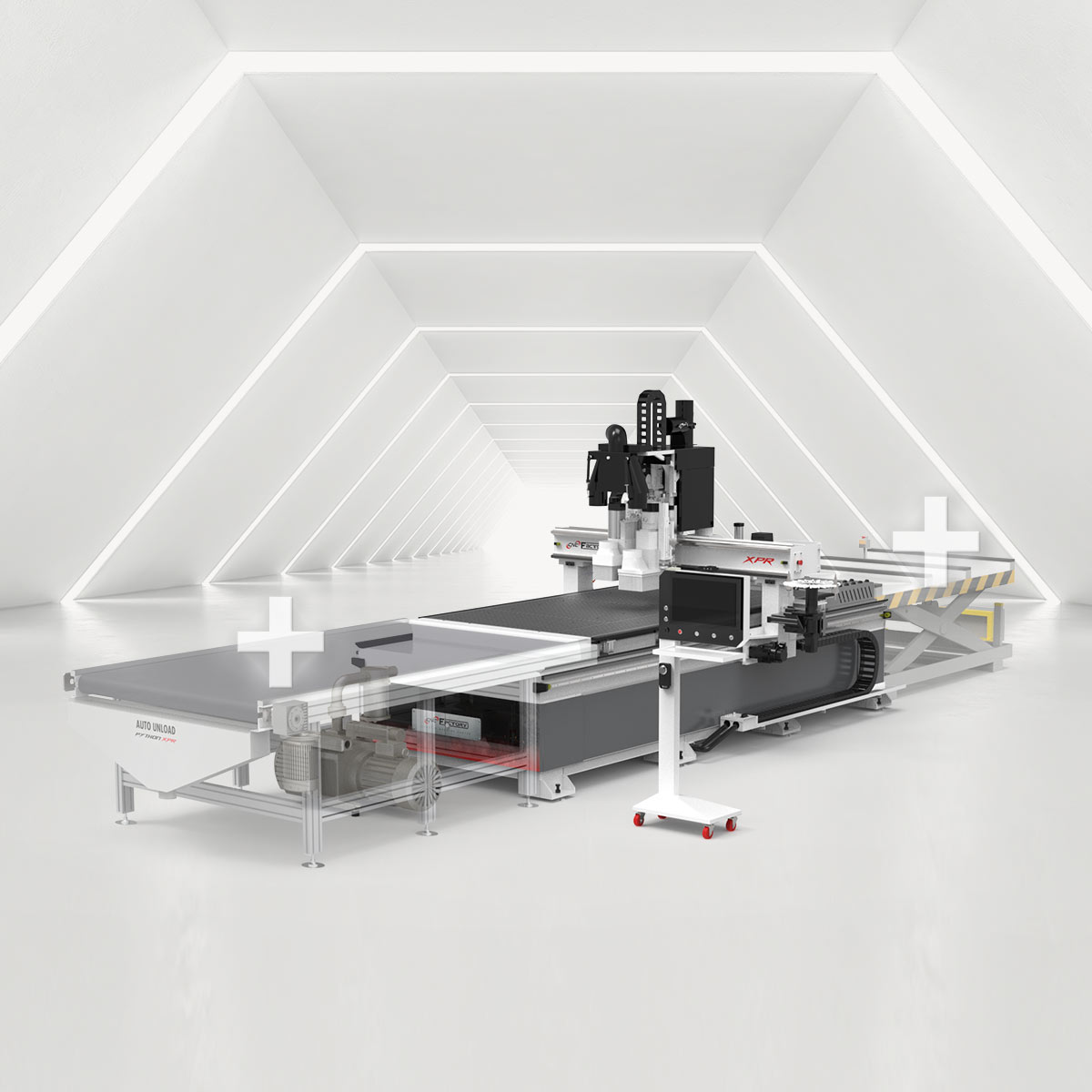

The Sidewinder is pre-wired for expansion so you can just plug in additional equipment as you need them, whether months or years down the road. These include drill & marking blocks which let you cut and mark parts faster, extra vacuum ports to increase hold down, mister kits when cutting light metals, loading and unloading tables to eliminate heavy lifting, and robotic material alignment.

Note that true expandability is not just a matter of adding anything to your machine, as retrofitting for other brands can come at a cost, void your warranty, or require additional training/expert installation. For the Sidewinder, you can plug & play the upgrades on your own, when you’re ready for them, all while using the same program you’ve been trained on Day 1.

Robotic Material Sensing is a patent-pending innovation only available with CNC Factory. It automatically detects the thickness of the material and the corresponding height of its required tool. This “sensing” allows the dust hood to hover at the perfect spot over the material, creating a seal to prevent dust from escaping without squishing the dust brush, whether you are switching from thin to thick materials, or are using short or longer tools.

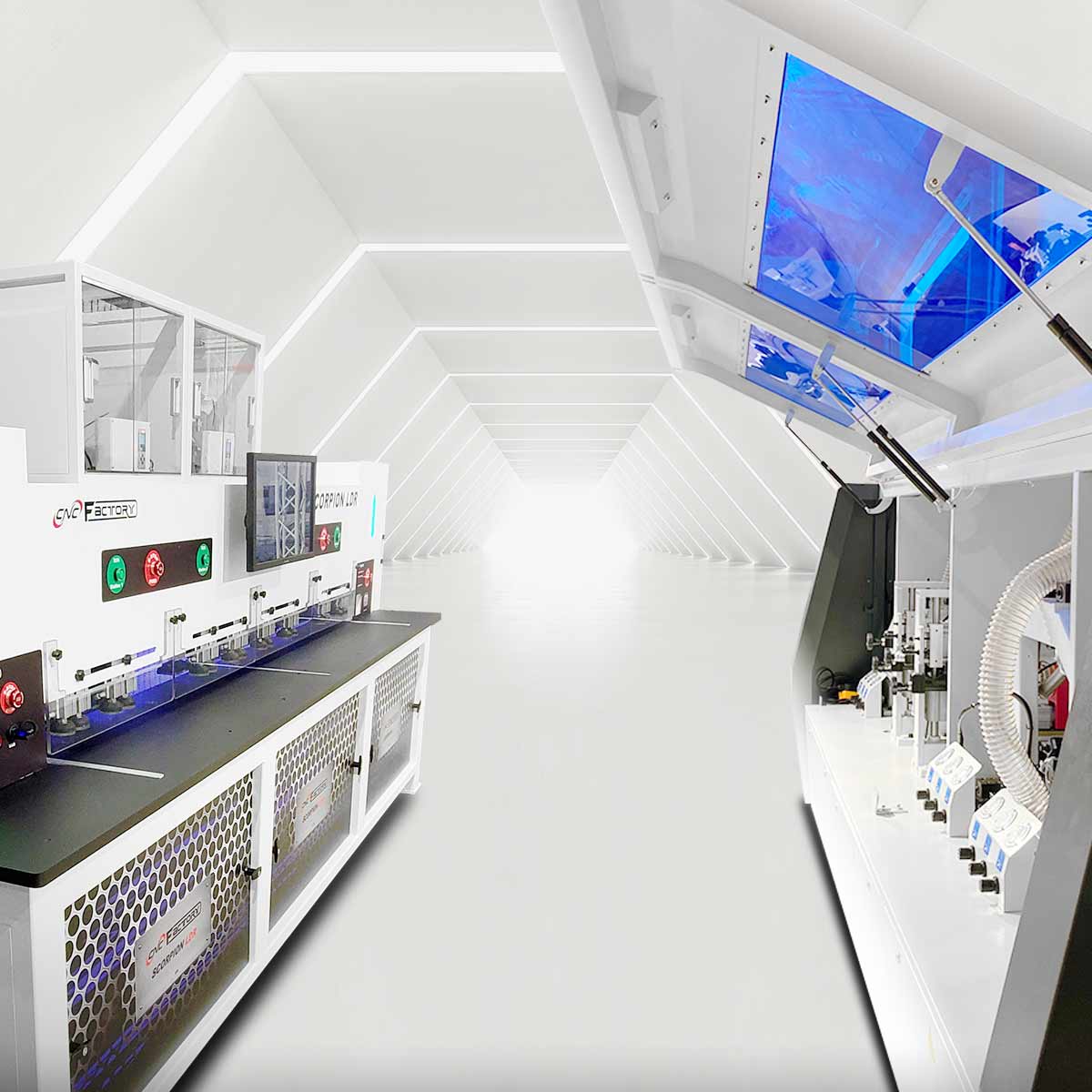

The Sidewinder has one of the largest CNC router screens which allows designing at the machine with your CAD/CAM software, so your operator never needs to leave the production spot. A larger screen also means you can have a more graphical interface (larger buttons, more detailed illustrations) which results in fewer errors. Its PC-front end also allows for our Tech Support to diagnose and fix any issues remotely.

Instead of manually cranking vacuum valve levers under the machine, you can simply adjust workholding by pressing a few buttons on the touchscreen and— voila, the vacuum valves adjust automatically! The Sidewinder also alerts the operator if there is insufficient vacuum before cutting, as well as automatically turns off vacuum when unloading processed parts. That’s definitely less thinking for the operator.

It means the Sidewinder knows its position at all times and does not need to find its starting point or “home” every time it is turned on, unplugged or reset. For older machines, homing is required daily— which wastes a few good minutes of production time. And, forgetting to “home” almost always results in inaccurate cuts.

No. Any unskilled operator, with or without CNC experience, can be trained to use the Sidewinder in just 1 day. Its graphical interface is in English.

No. Rubber belts get loose over time and can cause backlash and inaccurate cutting. Worse, they require periodic retensioning for maintenance. The Sidewinder uses 5G helical rack & pinion on the X & Y axes for consistent and absolute positioning.

The Sidewinder self cleans by activating dust extraction suction under the unloading arm in the center of the table, and spraying air on the sides to dislodge larger particles— all while unloading your parts. This ensures a clean spoilboard in 30 seconds with no human intervention.

Having tools on a rotary carousel allows rapid tool changes in under 8 seconds. More importantly, it creates an unobstructed table so loading of materials can be done on all 4 sides of the machine.

If cutting regular cabinets with the drill block, the Sidewinder can cut about 50 sheets (including the time for loading, unloading & cleaning) in an 8-hour shift. Note that cutting time increases together with the intricacy of your design. When fully upgraded with the loading & unloading tables, the Sidewinder can cut about 60 sheets in an 8-hour shift.

We are happy to answer any questions you may have.

714-581-5999

4021 West Chandler Ave, Santa Ana, CA 92704

sales@cncfactory.com

We also offer in-house and 3rd party financing to cover 50-100% of your purchases.

See Financing Options