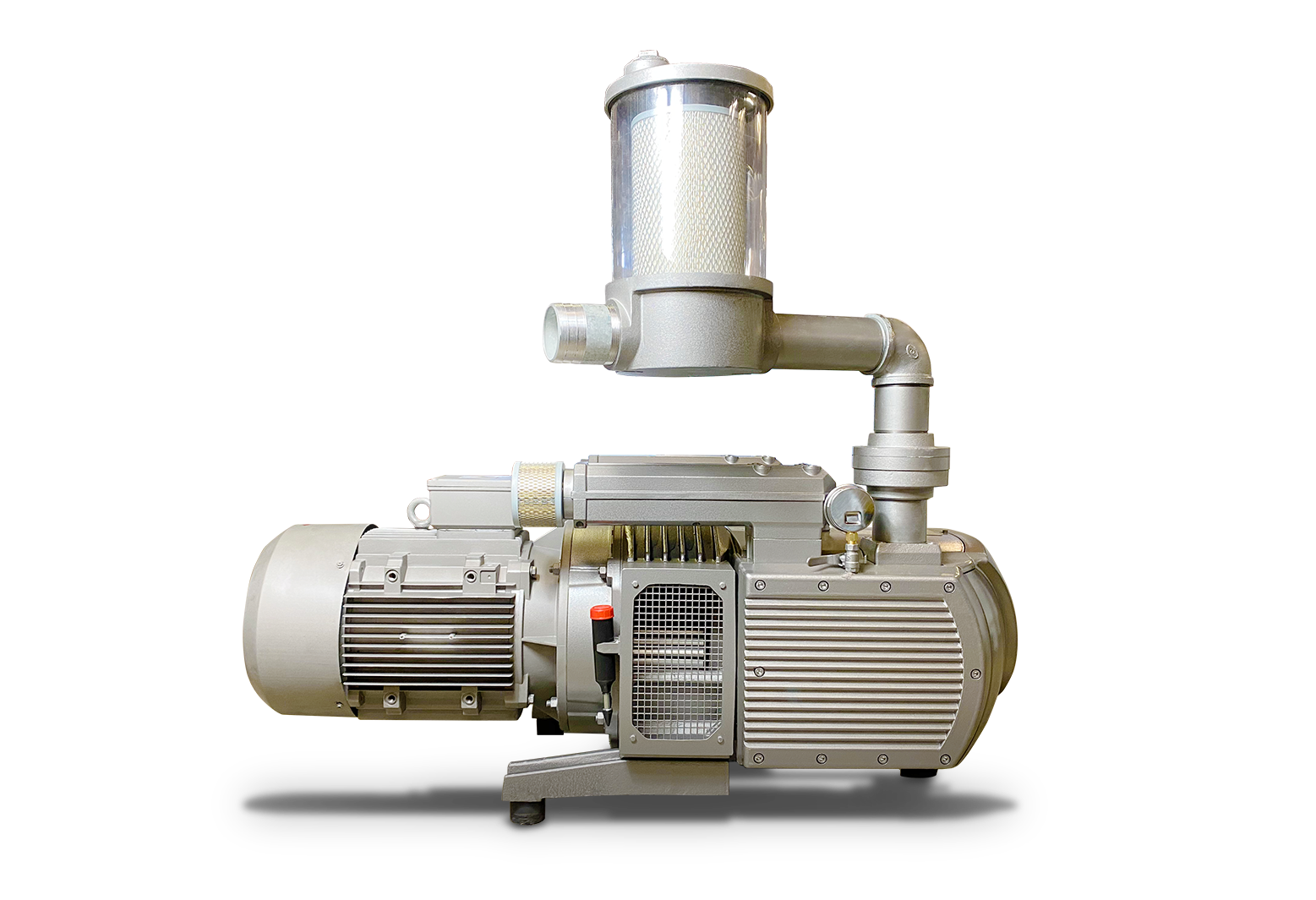

Vacuum Pumps

Constant Hold Down Communication. Energy-saving.

Download Specs Sheet

Download Brochure

Watch the Video

Share this

Footprint |

|||

| Footprint | 49in L x 24in W x 34in H | ||

|---|---|---|---|

Mechanical/Electrical Requirements |

|||

| Power | 208-240 volts, 3-phase, 50amps

208-240 volts, single phase, 70amps |

Air | 8 bar, 9cfm, 120 psi |

Support & Warranty |

|||

| Machine Warranty | 18 months | Support | 2-year machine support

Free CNC University training On-site support options available Online Knowledge Center access |

|---|---|---|---|

|

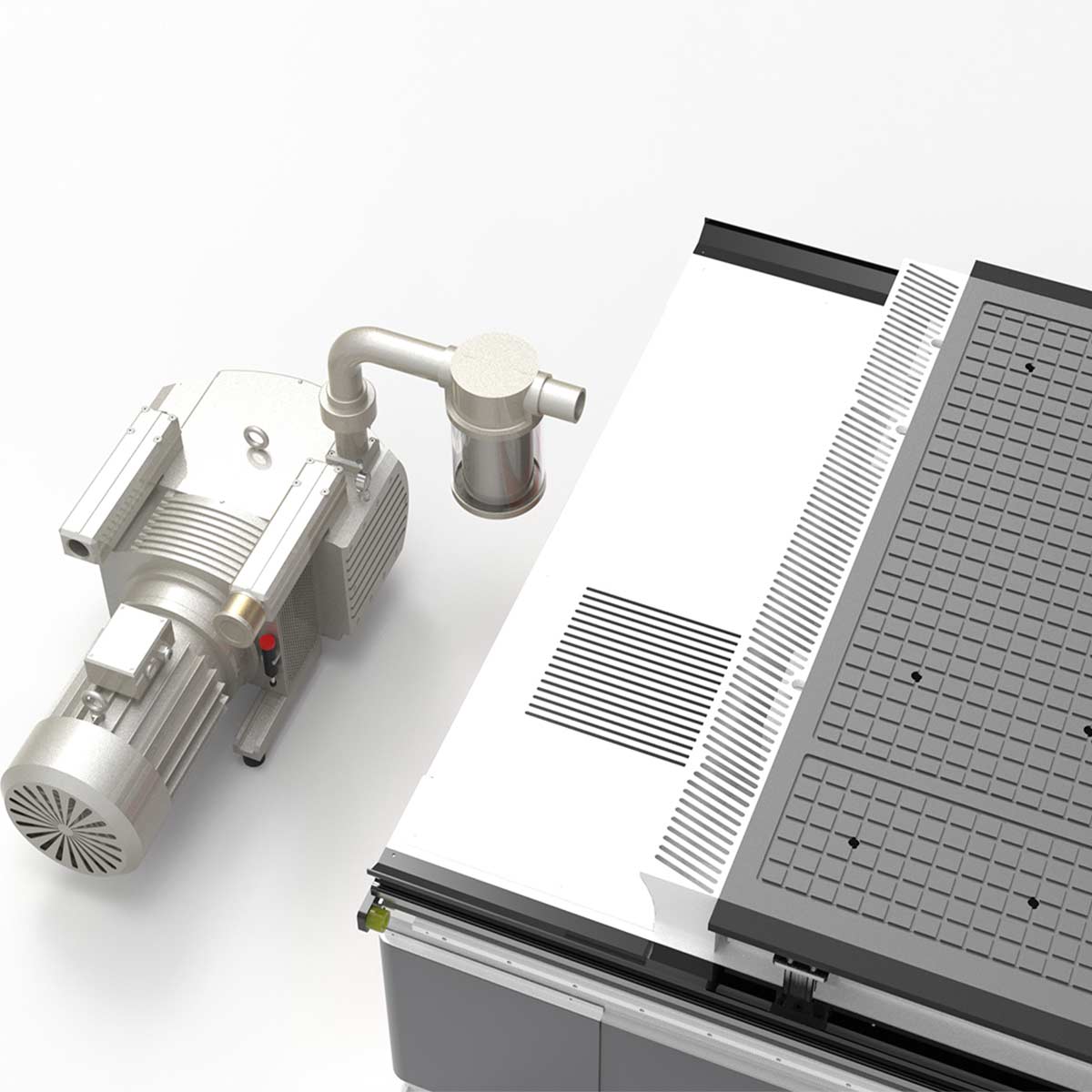

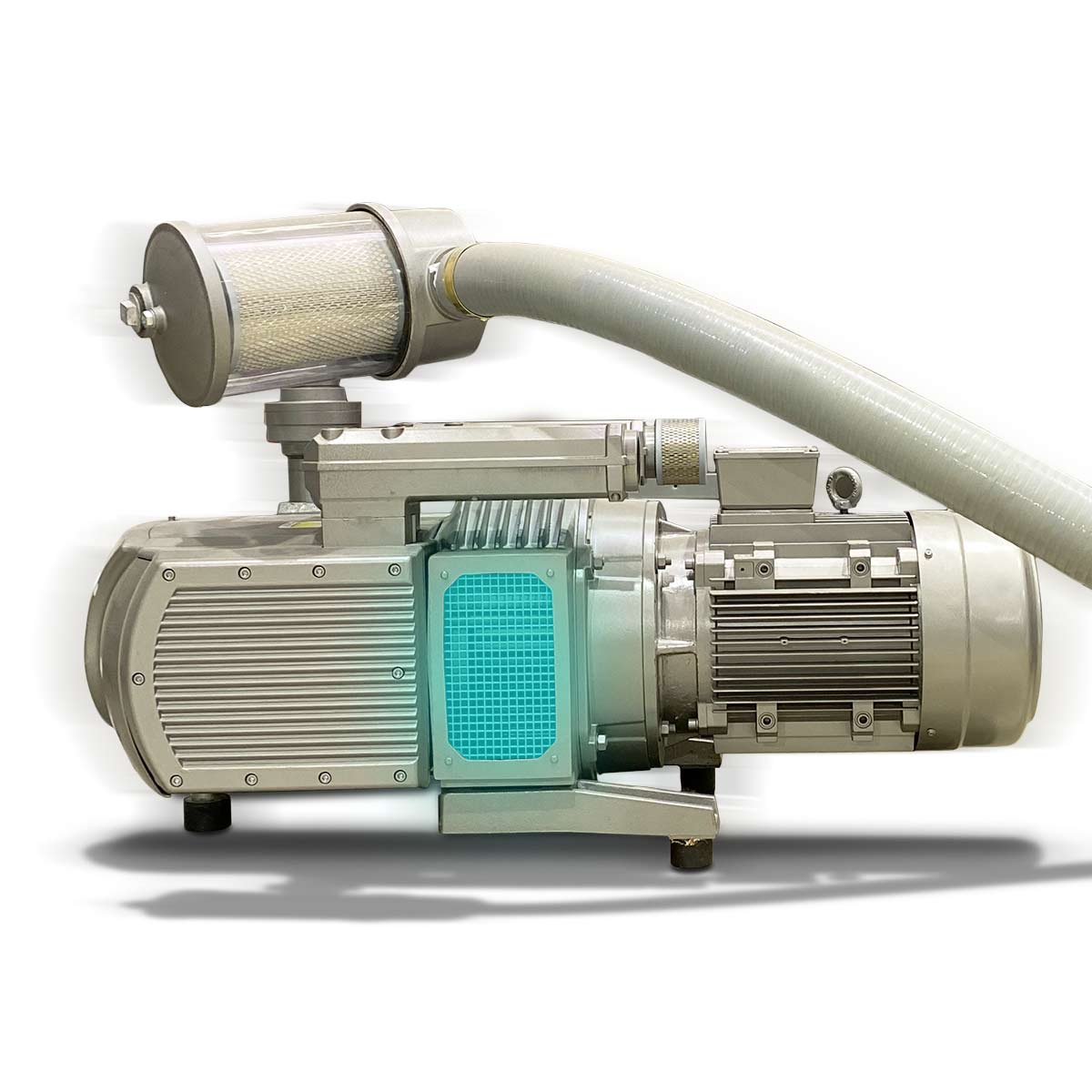

Install the V300 pump in a position for easy maintenance access. However, it should be 12” away from any wall or obstacle to ensure that airflow and cooling is not impeded. The ambient temperature should not exceed 110 degrees. If using our upgraded 5G CNC routers, we recommend placing it under our unloading tables. |

Regular maintenance of the V300 pump allows it to maintain optimum operating conditions. Each maintenance cycle depends on how much the pump is used as well as its work environment (i.e. degree of dust generated and hours used). Minimum maintenance should be performed monthly until a regular maintenance schedule can be established based on your usage and environment.

Minimum maintenance includes cleaning the intake filter and cylinder air duct, lubrication every 300 hours of use, and annual vane replacement.

We are happy to answer any questions you may have.

714-581-5999

4021 West Chandler Ave, Santa Ana, CA 92704

sales@cncfactory.com

We also offer in-house and 3rd party financing to cover 50-100% of your purchases.

See Financing Options