Edgebanders

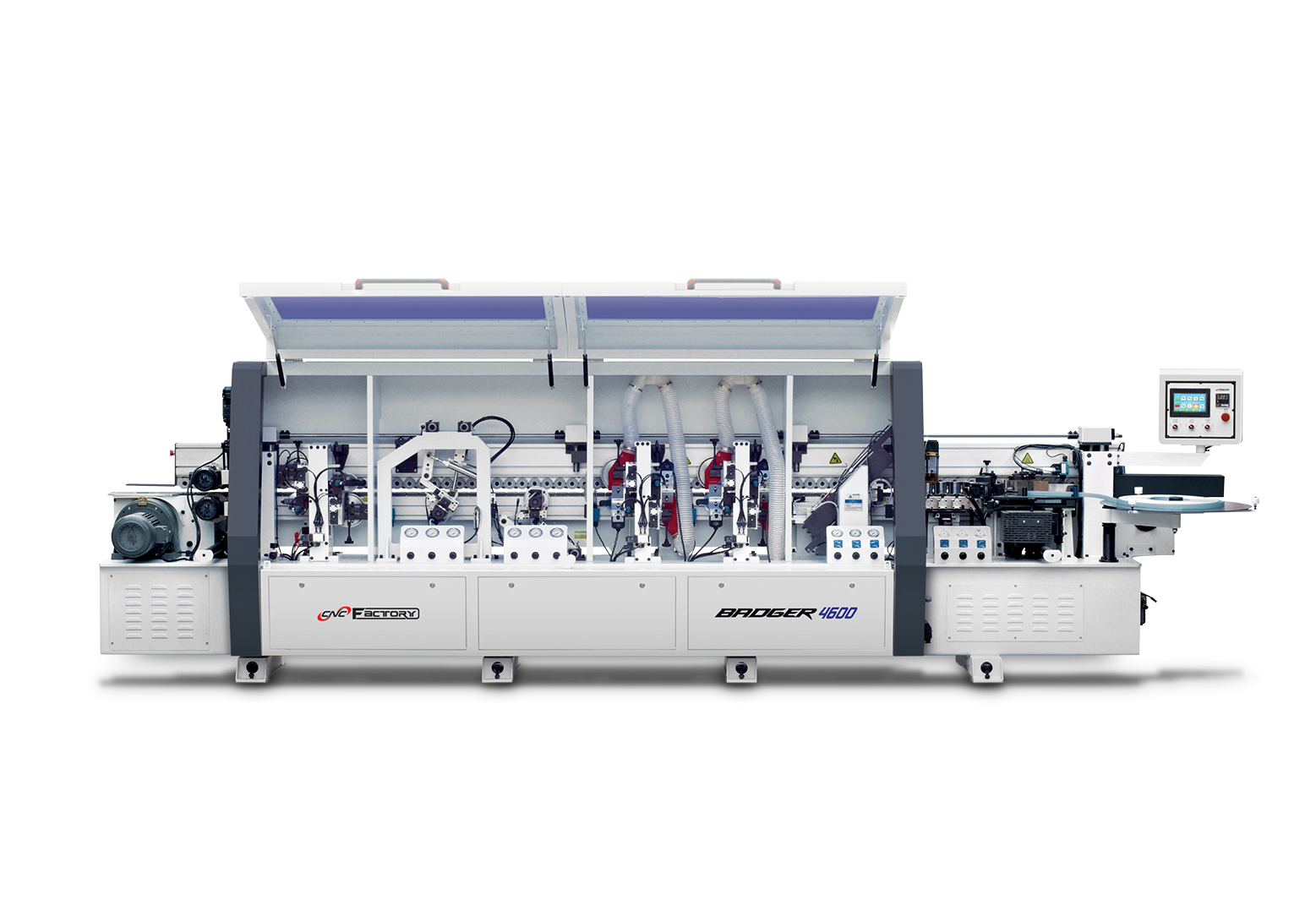

Driverless Operations. Perfect Finish. With Corner-Rounding. A 5th Generation automatic digital edgebander with corner-rounding designed for profitability, speed, and ease of use for the woodworker. Apply edge banding material flawlessly with a touch of a few buttons. Its compact technology gives it the smallest footprint for an edgebander with its features, plus it’s return-conveyor ready for returning large processed materials back to the operator.

BUILD YOUR OWN BADGER 4600

Request a Consultation

Download Specs Sheet

Download Brochure

Watch the Video

Share this

Footprint |

|||

| Footprint | 6001.5mm L x 1782.5mm W x 1584mm H

Weight: 4200 lbs. (for Badger 4600) & 5500 lbs. (For Badger 4800) |

||

|---|---|---|---|

Specifications |

|||

| Controller | Digital touch screen controls | Feed System | Track feed 40 Ft/Min. with digital feed rate override |

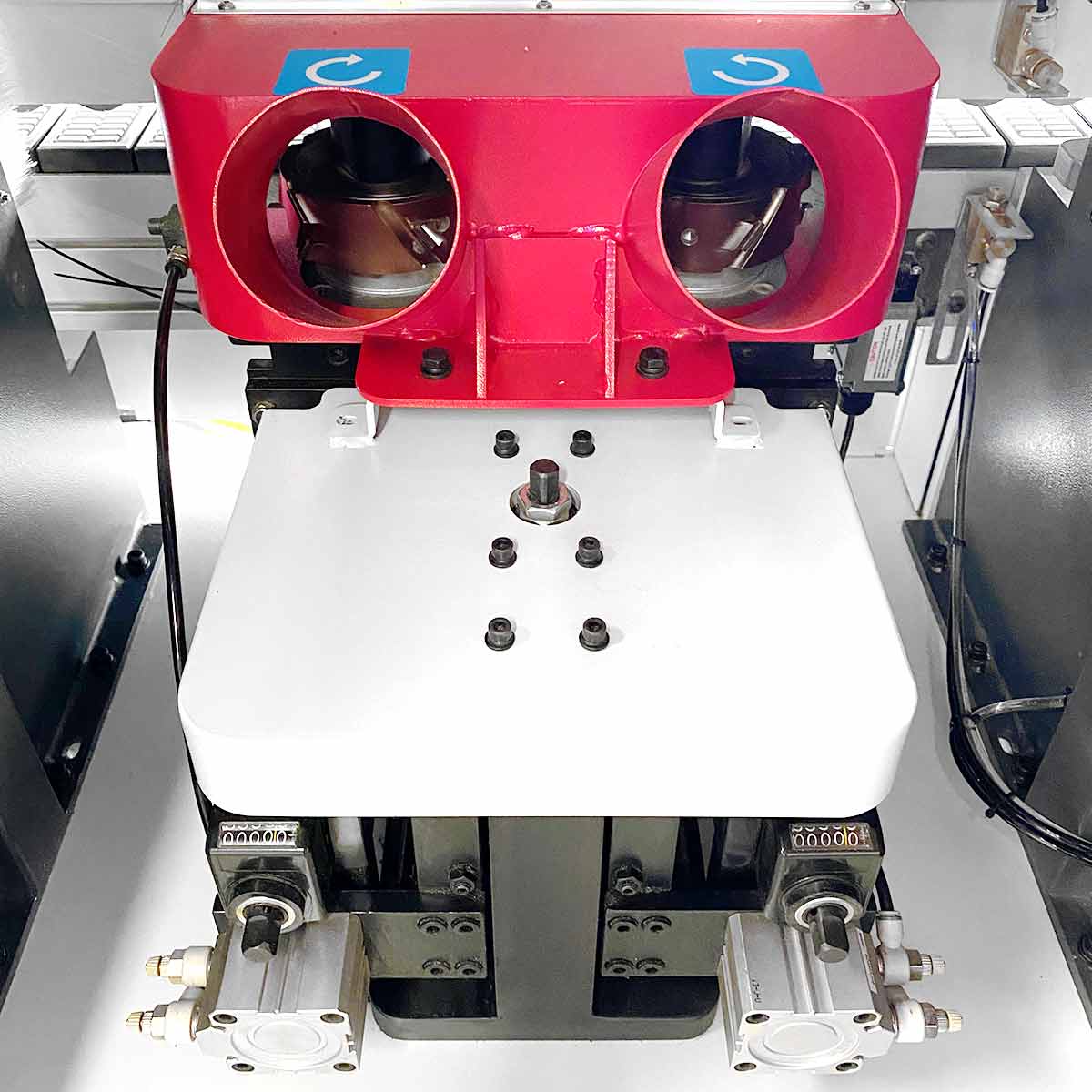

| Tape Thickness | 0.4mm to 3mm | Top/Bottom Fine Trim | Dual H.F. motors with 6-wing insert cutters |

| Front/End Trim | Dual independent H.F. Cutters | Pressure Rollers | 3 independent material pressure rollers with on board adjustments |

| Scraper | Top and bottom edge scrapping | Buffing | Dual buffing motors with 6” buffing wheels |

| Heating | Pellet glue up to 200°C or 400°F degrees. 2 Liter glue tank capacity | Panel Size | 3/8” min. to 1 15/16” Max Thickness.

Min. Width: 3 1/2” Min. Length 4.75” |

Mechanical/Electrical Requirements |

|||

| Power | 208-240 volts, 3 phase. 30amps.

208-240 volts, single phase. 35amps. |

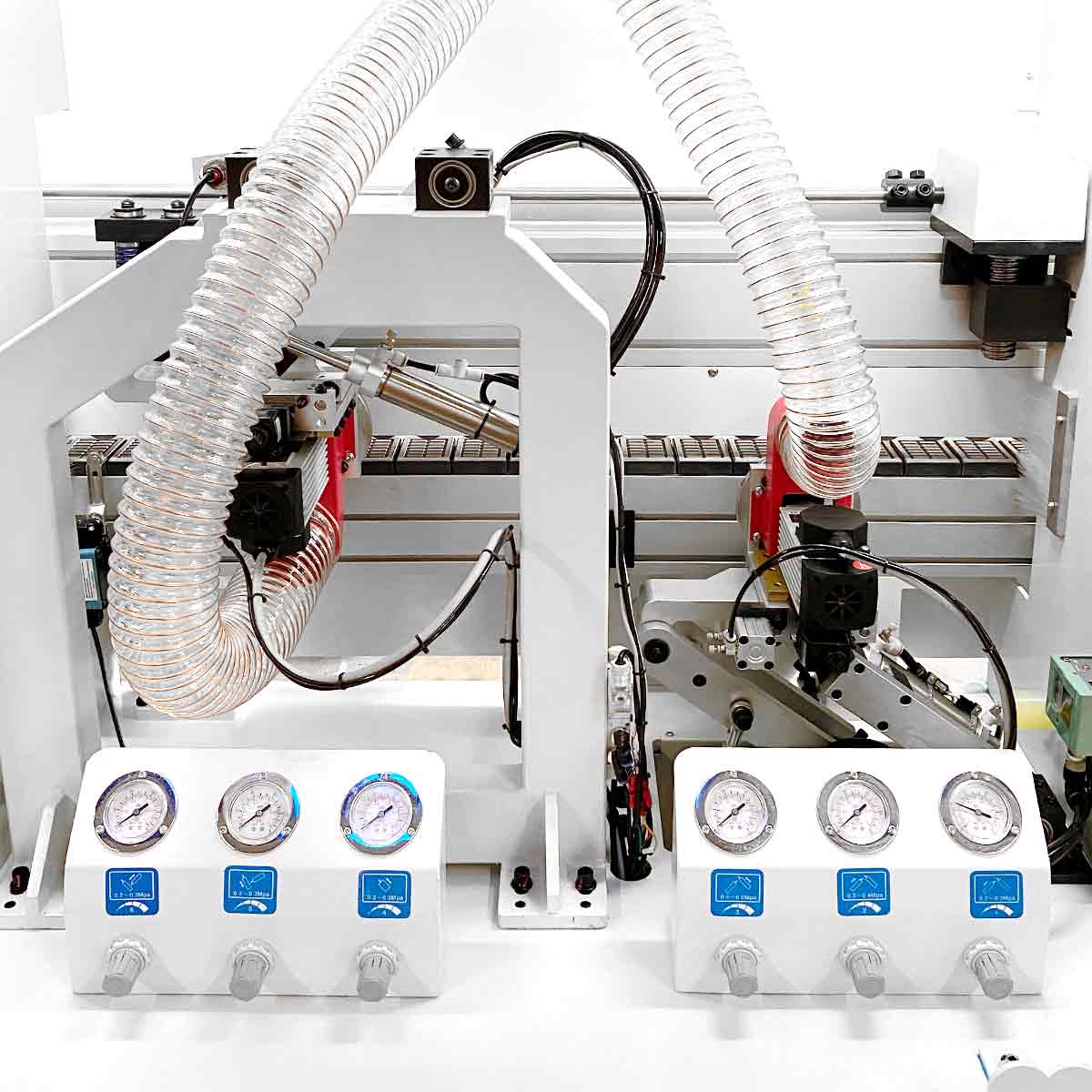

Air | 8 bar, 9cfm, 120 psi |

| Dust Collection | 5.5kw + 3500 cfm | ||

Production Upgrade |

|||

| Production Upgrade | Pre-Mill Station | ||

|---|---|---|---|

|

Sometimes, when cutting pieces for edgebanding, the thickness of the edgebanding tape is not calculated and this creates gaps during installation. The Pre-mill station tapers off a layer of the material that is equal to the thickness of the edge banding tape. As a result, your final edge banded material will have the same size as the original material you fed into the machine. The pre-mill also cleans up rough edges if you cut your parts with a table saw. Adding a pre-mill station upgrades your model into a Badger 4800 [see in 3D here]. | ||

Anytime Upgrade |

|||

| Anytime Upgrade | Return Conveyor | ||

|

The Badger is designed to easily connect to a return conveyor, which brings back edge banded material as long as 100” (8 feet), back to the operator for non-stop edgebanding. | ||

Support & Warranty |

|||

| Machine Warranty | 18 months | Support | 2-year machine support

Free CNC University training On-site support options available Online Knowledge Center access |

|---|---|---|---|

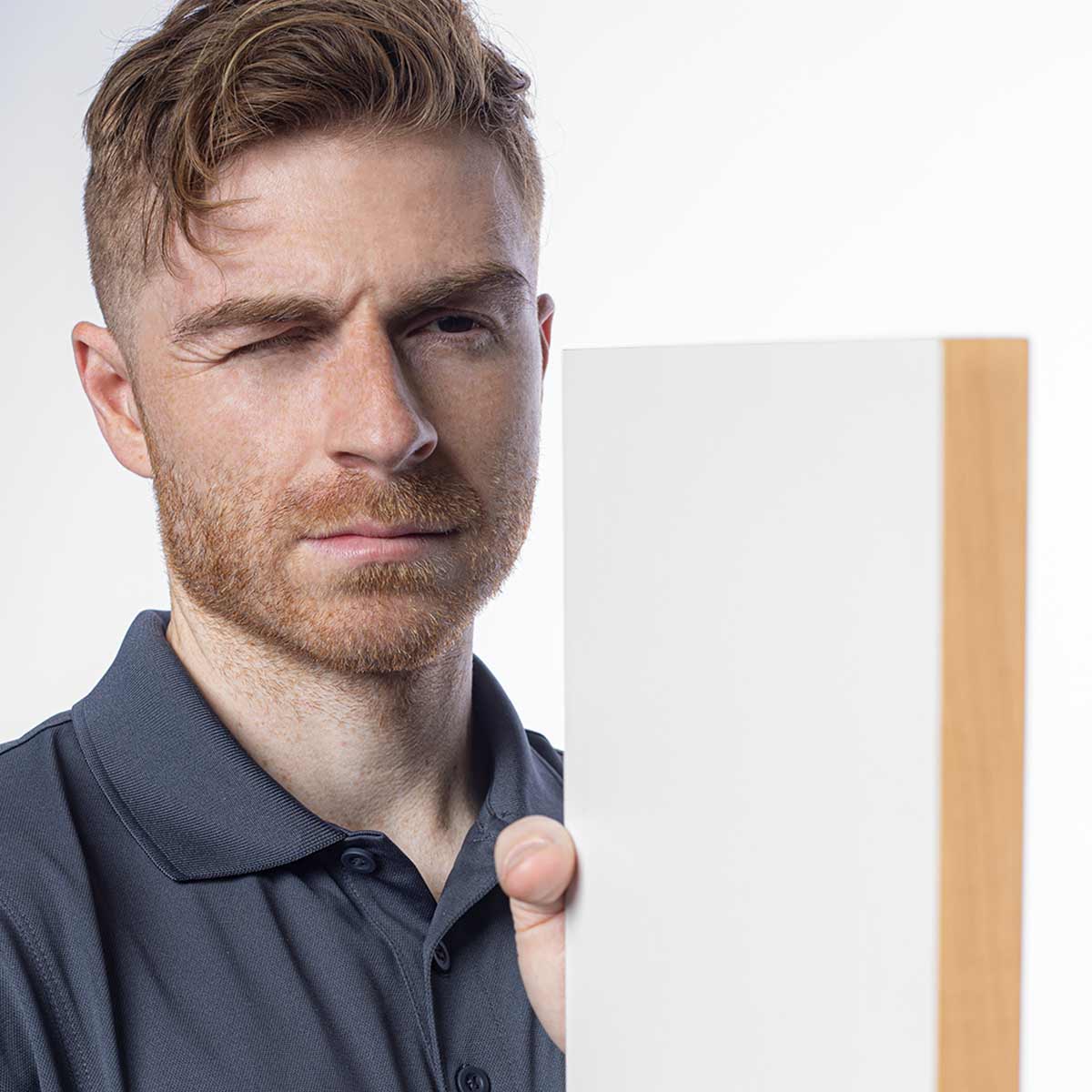

Not a lot. Most of the technical adjustments needed will already be pre-set during installation. After your air, power & dust extraction are hooked up, there is little to do but to make sure you have enough consumables (glue, cleaning liquid, lubrication, edge banding tape), and to measure the size of your materials and set them on the machine. Anyone can be trained to use the Badger in just a few hours.

Since there are countless types of main and edge banding materials, the perfect settings to get the results you want, based on your unique materials, can only be finalized after a few ‘trial & error’ runs. Thankfully, the Badger has independent motor controls for each step of the edge banding process, so it is highly customizable. All you need to do is turn the control knobs on each station to adjust settings.

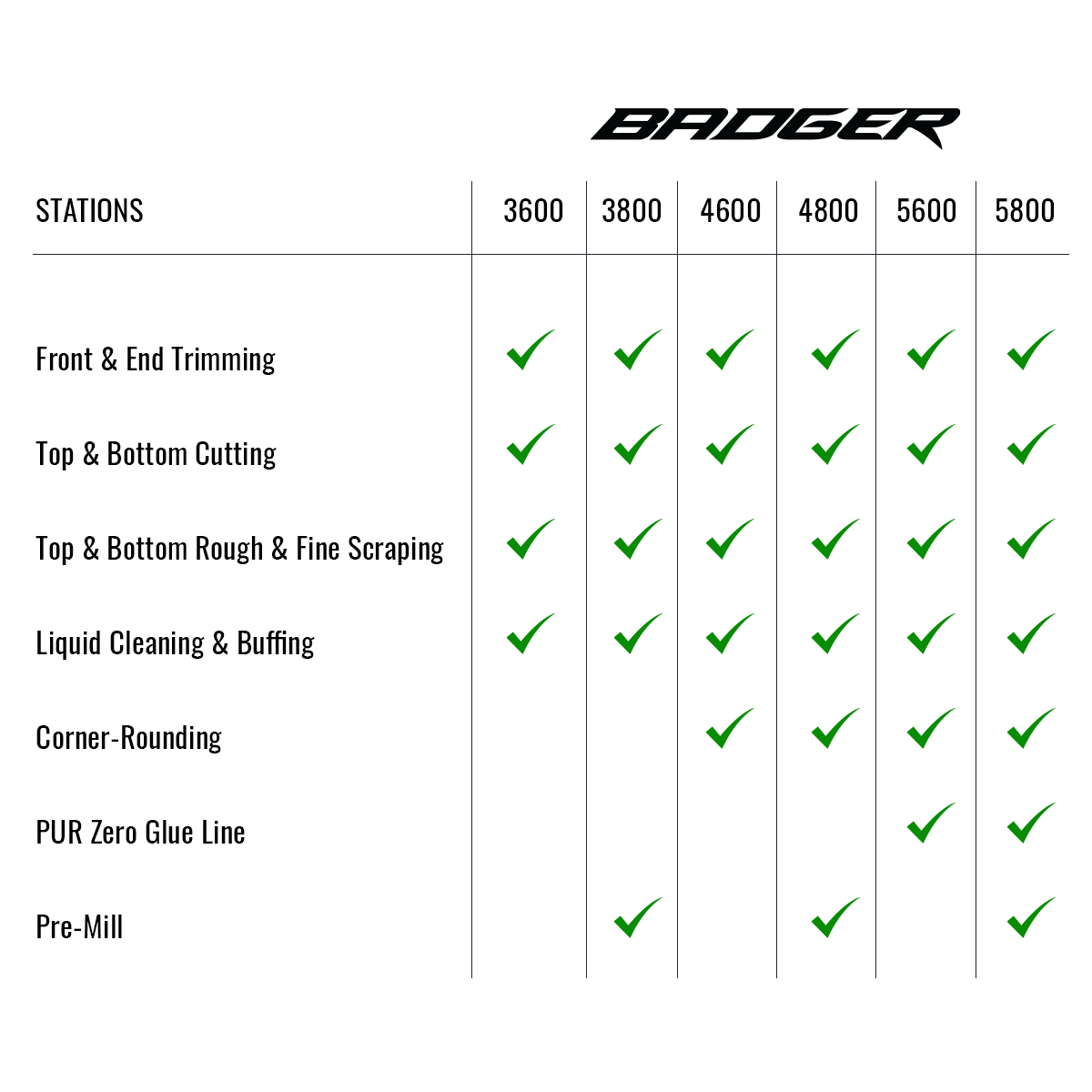

Here are the main difference by features:

We are happy to answer any questions you may have.

714-581-5999

4021 West Chandler Ave, Santa Ana, CA 92704

sales@cncfactory.com

We also offer in-house and 3rd party financing to cover 50-100% of your purchases.

See Financing Options