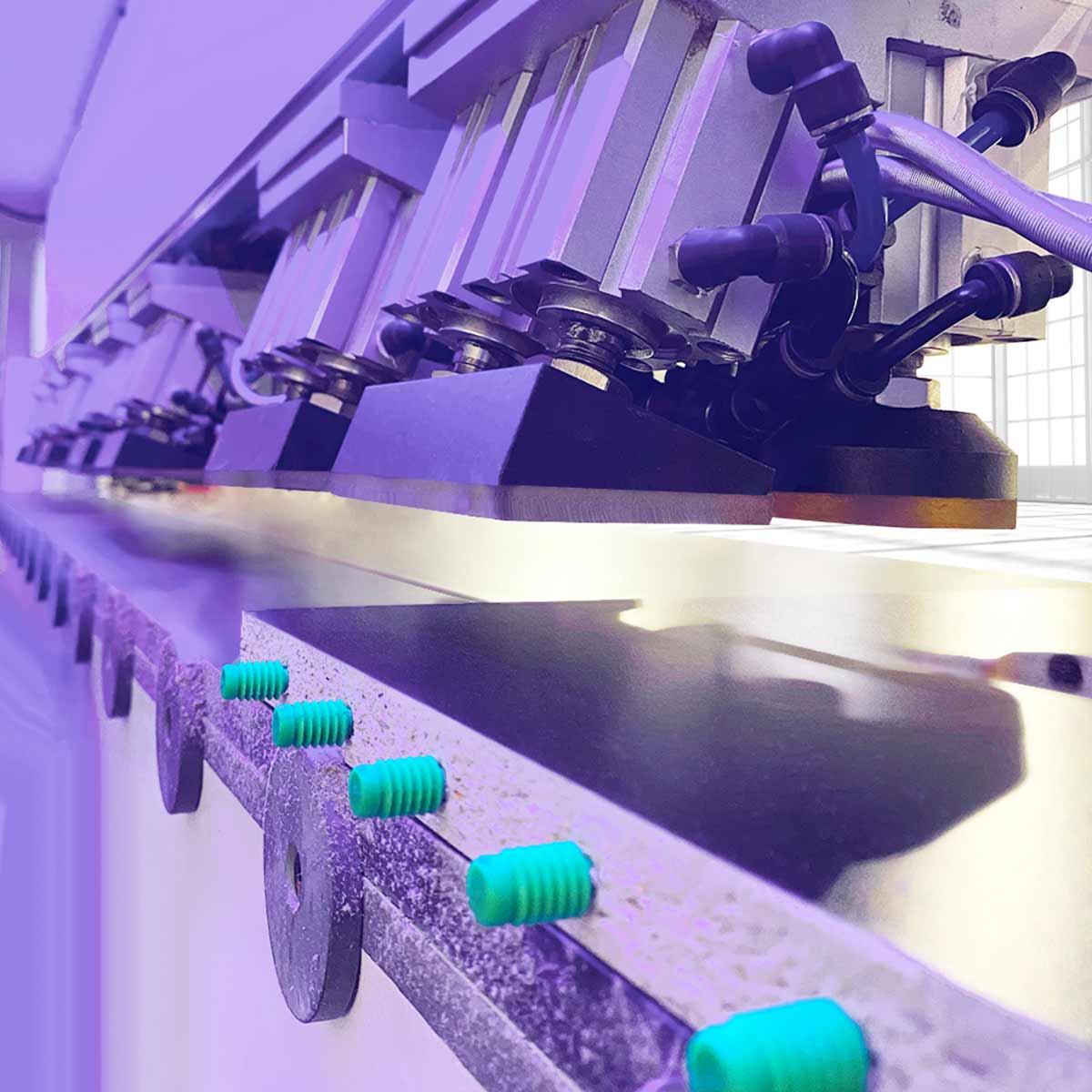

CNC Insertion

Driverless Operations. Non-Stop Flat Pack Production.

BUILD YOUR OWN SCORPION LDR

Request a Consultation

Download Specs Sheet

Download Brochure

Watch the Video

Share this

Footprint |

|||

| Footprint | 143”W x 55”L x 79.75”H | ||

|---|---|---|---|

Specifications |

|||

| Robotic Drilling | Dual 8mm, Dual 8.2mm, Single 5mm | Available Configurations | LockDowel H-Clip, Channel Lock, Mini, wooden dowel

FastenLink, Lammello and Ovvo |

| On-Board Spindle | 3HP air-cooled spindle with 0.375 Cutter | Material Hold-Down | Auto-sensing material length for automatic hold-down up to 96”

6 hold down clamps per station |

| Workstations | 4 workstations with embedded and auto alignment rails | Robotic Insertion Guns | Equipped with 2 feeders and guns. Upgradable to 4. |

| Lubrication | On-board pressurized lubrication system | CNC Control | 6-axis robotic 5th generation CNC controller |

| Front End | 21” touch screen, keyboard, camera and barcode reader | Communication | Virtual, with on-board WiFi and ethernet connection |

Mechanical/Electrical Requirements |

|||

| Power | 208-240 volts, 3 phase. 30amps.

Single phase option available for additional charge. |

Air | 1/2” inlet, 8 bar, 10cfm, 120 psi |

| Dust Collection | 1500 cfm for main 4” port | ||

Production Upgrade |

|||

| Production Upgrade | Additional Guns | ||

|---|---|---|---|

| Outfit your Scorpion up to a total of 4 feeders and guns, so you can have 4 independent work stations for high-yield production. | |||

Support & Warranty |

|||

| Machine Warranty | 18 months | Support | Free lifetime technical support (phone & email)

Free CNC University training On-site support options available Online Knowledge Center access |

|---|---|---|---|

The Scorpion was built for invisible fasteners that eliminate messy glue and dowels, screws and staples. It is compatible with fasteners such as:

Scorpion has the patented high-speed dual drilling so it’s the only machine that drills 2 holes at a time which reduces processing time by more than 50%. It also has a patent-pending laser-guided robotic measuring for quick and accurate measurements of your panels.

It has 5th generation helical rack and pinion gear movement on the X and Y axes. It offers the highest resolution control especially at high speeds with faster and smoother travel positioning times with precision linear guide rails on all axes.

The Scorpion has a 96” material working space. You may also divide it into a maximum of 4 workstations (each with 24” working space).

We are happy to answer any questions you may have.

714-581-5999

4021 West Chandler Ave, Santa Ana, CA 92704

sales@cncfactory.com

We also offer in-house and 3rd party financing to cover 50-100% of your purchases.

See Financing Options